When it comes to RF (Radio Frequency) testing, selecting the right chamber is crucial for achieving accurate, repeatable, and reliable measurements. Whether you are working in aerospace, defence, automotive, or telecom sectors, investing in a High-Performance RF Chamber ensures compliance, efficiency, and safety. Below, we look at the top ten features to consider before making your RF chamber purchase.

- Optimal Shielding Effectiveness

The first and foremost feature is shielding effectiveness (SE). A high-performance RF chamber should have SE levels of at least 100 dB across a wide frequency range, protecting tests from external interference and preventing leakage. This is essential for EMC (Electromagnetic Compatibility) and antenna measurements, where even minor leakage can distort results.

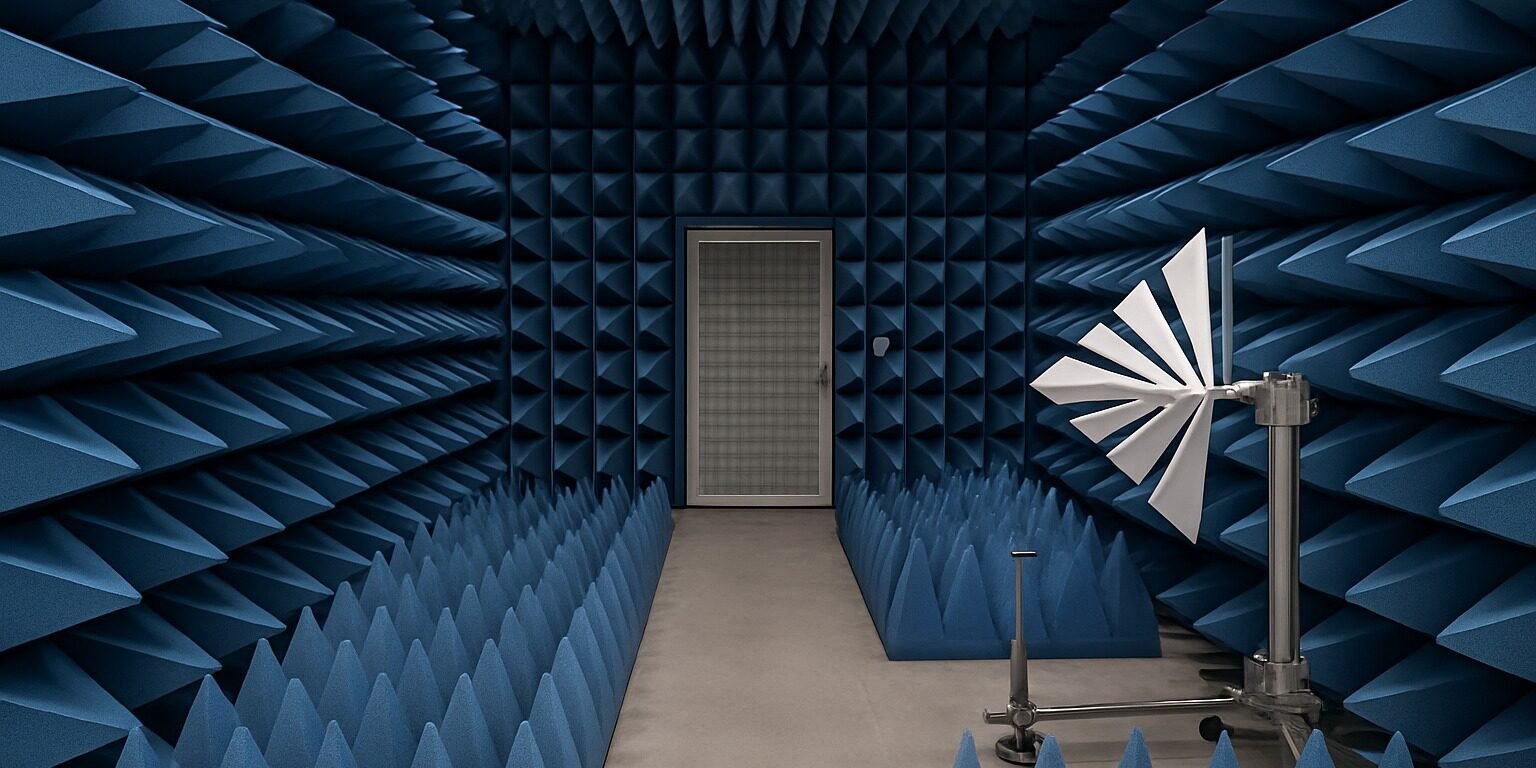

- Quality of RF Absorbers

The chamber’s absorbers significantly impact its performance. Look for:

- Hybrid absorbers(pyramidal + ferrite tiles) for broadband coverage

- Low reflectivity(e.g., -60 dB at desired frequencies)

- High power handling capability

Premium absorber material ensures minimal reflections, making the chamber suitable for antenna pattern measurements, RCS (Radar Cross Section) testing, and other precision applications.

- Frequency Range Compatibility

Your chamber should cover the full frequency range required by your tests. Common ranges include:

- 30 MHz – 18 GHz for EMC compliance

- Up to 40 GHz or higher for advanced radar and satellite applications

Always future-proof your investment by choosing chambers with wider frequency coverage than your immediate needs.

High Performance RF Chamber

- Size and Test Volume

The internal size of the chamber determines what equipment can be tested. Consider:

- Quiet zone size– area with minimal reflections for accurate measurements

- Overall chamber dimensions– to fit your largest DUT (Device Under Test)

A chamber too small for your DUT may compromise the measurement accuracy due to near-field effects and reflections.

- Type of Chamber (Anechoic, Semi-Anechoic, Compact)

Different test requirements need different chamber types:

- Full anechoic chambers for far-field antenna and RCS testing

- Semi-anechoic chambers for EMC immunity and emissions testing

- Compact antenna test ranges (CATRs) for mmWave and satellite testing

Choosing the appropriate type ensures you achieve the required measurement accuracy efficiently.

- Turntable and Positioner Capabilities

For antenna and RCS measurements, an integrated precision turntable and positioner are essential. Check for:

- Load capacity matching your DUT

- High angular accuracy (≤0.05°)

- Smooth and vibration-free movement

Automated positioners enhance productivity by enabling fast and repeatable measurements at multiple angles.

- Instrumentation Integration and Cabling

Efficient cable management and instrumentation integration options are critical. Look for:

- RF feedthrough panels with multiple connectors

- Fibre optic feedthroughs for control and data transmission

- Shielded penetrations for power and cooling lines

Proper integration reduces setup time and ensures minimal signal loss or interference.

- Safety and Access Provisions

Safety is paramount. Ensure the chamber has:

- Emergency exit push buttons inside

- Door interlocks to prevent accidental exposure to high power RF

- Adequate ventilation or HVAC systems for cooling during high power tests

Additionally, check door sizes and ramp availability to ensure smooth movement of large DUTs.

- Accreditation and Standards Compliance

High-performance RF chambers should be designed and installed to comply with standards such as:

- ANSI C63.4, CISPR 16-1-4 for EMC testing

- IEEE-299 for shielding effectiveness

- ISO 17025-accredited calibration for guaranteed performance

Standards compliance ensures your chamber will be accepted by regulatory bodies for product certification.

- Reputation of Manufacturer and Support

Finally, consider the manufacturer’s reputation and support services. A chamber is a long-term investment; thus, ensure:

- Proven global installations and references

- Availability of local technical support and maintenance

- Long-term spare parts availability

Choosing a trusted manufacturer ensures your chamber maintains performance for decades with minimal downtime.

Selecting a high-performance RF chamber is a significant decision that affects your testing capabilities, operational efficiency, and business reputation. From shielding effectiveness and absorber quality to chamber type, instrumentation integration, and manufacturer support – each feature plays a vital role in ensuring precise and reliable test results.