Table of Contents

- What Is a 5G OTA Test Chamber?

- Core Design of a 5G OTA Test Chamber

- Materials Used in 5G OTA Chambers

- Why Material Matters

- Key Performance Metrics Measured

- Standards and Certifications

- Chamber Types Used in 5G Testing

- Environmental & Mechanical Design Considerations

- Challenges in 5G OTA Testing

- Performance Optimization Techniques

- Real-World Applications

The evolution of 5G has pushed wireless testing into a new era of complexity. Unlike earlier generations, 5G devices operate across multiple frequency bands, use advanced beamforming techniques, and integrate compact multi-antenna systems. This makes traditional conducted testing insufficient.

That’s where 5G Over-the-Air (OTA) testing comes in.

A 5G OTA Test Chamber is a specialized RF-controlled environment designed to measure real-world wireless performance without physical cable connections. In this blog, we’ll explore:

- What happens inside a 5G OTA test chamber

- Design architecture and layout

- Materials used in construction

- Performance parameters and metrics

- Testing standards and certifications

- Challenges and optimization strategies

Let’s step inside.

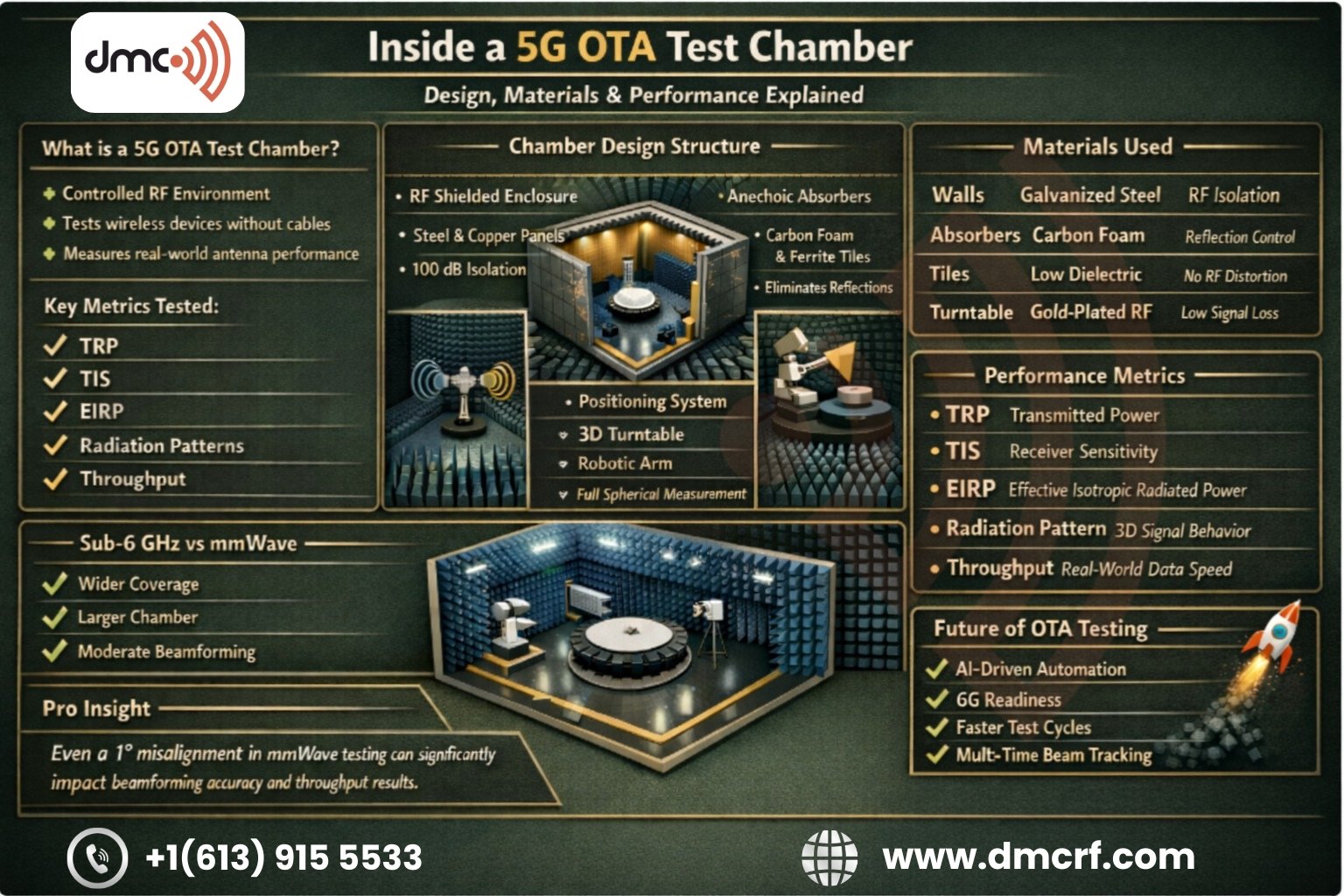

What Is a 5G OTA Test Chamber?

A 5G OTA test chamber is a shielded, RF-isolated environment used to evaluate wireless device performance under controlled, repeatable conditions. Instead of connecting antennas via coaxial cables, engineers measure how signals are transmitted and received in free space.

This approach is essential for:

- Smartphones

- IoT devices

- 5G routers

- Automotive telematics units

- Wearables

Particularly in Sub-6 GHz and mmWave frequency bands, OTA testing ensures accurate measurement of antenna efficiency, beam patterns, and total radiated performance.

Core Design of a 5G OTA Test Chamber

A well-designed OTA chamber ensures three critical objectives:

- RF isolation

- Signal absorption

- Controlled measurement geometry

1. RF Shielded Enclosure

The chamber walls are typically constructed from:

- Steel panels

- Copper-lined shielding

- EMI-sealed doors

This prevents external RF interference and ensures measurement repeatability.

2. RF Absorbers

Inside the chamber, walls are covered with RF absorbing materials such as:

-

- Pyramidal foam absorbers (Sub-6 GHz)

- Hybrid absorbers

- High-density absorbers (for mmWave)

These materials prevent signal reflections, simulating a “free-space” environment.

3. Measurement System Components

Key components include:

- Probe antennas

- Positioner / turntable

- Device Under Test (DUT) mount

- Network analyzer or communication tester

- Beamforming test systems (for mmWave)

Materials Used in 5G OTA Chambers

Material selection directly impacts chamber accuracy and performance.

| Component | Material Used | Purpose | Frequency Suitability |

|---|---|---|---|

| Chamber Walls | Steel + Copper Shielding | RF Isolation | Sub-6 & mmWave |

| Absorbers | Polyurethane Foam | Signal Absorption | Sub-6 GHz |

| Hybrid Absorbers | Ferrite + Foam | Low-frequency absorption | Below 1 GHz |

| mmWave Absorbers | High-density RF foam | Short wavelength absorption | 24–40 GHz |

| Turntable | Low-reflection composite | DUT rotation | All bands |

Why Material Matters

At mmWave frequencies (24 GHz+), wavelengths are extremely short. Even minor reflections can distort measurements. That’s why absorber geometry, density, and placement are critical.

Sub-6 GHz vs mmWave Chamber Differences

5G operates in two main frequency ranges:

- Sub-6 GHz

- mmWave (24 GHz and above)

Here’s how chambers differ:

| Feature | Sub-6 GHz OTA | mmWave OTA |

|---|---|---|

| Wavelength | Longer | Very Short |

| Absorber Type | Foam + Ferrite | High-density foam |

| Measurement Distance | Larger | Compact |

| Beamforming | Limited | Essential |

| Sensitivity to Reflection | Moderate | Extremely High |

mmWave testing requires tighter alignment, more precise calibration, and specialized probe configurations.

Key Performance Metrics Measured

Inside a 5G OTA test chamber, engineers measure several critical parameters:

1. TRP (Total Radiated Power)

Measures total transmitted power from the device in all directions.

2. TIS (Total Isotropic Sensitivity)

Indicates how well a device can receive signals from any direction.

3. EIRP (Equivalent Isotropically Radiated Power)

Used heavily in mmWave compliance testing.

4. Beam Pattern & Beam Steering

Evaluates directional performance and beamforming accuracy.

5. Radiation Pattern

Shows how signal strength varies spatially.

These metrics ensure that devices meet global compliance requirements and deliver expected user performance.

Standards and Certifications

Several organizations define OTA testing guidelines:

- CTIA – Cellular OTA certification standards

- 3GPP – Defines 5G NR performance specifications

- FCC – Regulatory compliance in the United States

- ETSI – European telecom compliance

Manufacturers must comply with these standards before commercial deployment.

Chamber Types Used in 5G Testing

1. Fully Anechoic Chamber (FAC)

Absorbers on walls, ceiling, and floor. Offers highest measurement accuracy.

2. Semi-Anechoic Chamber (SAC)

Reflective floor. Common for certain compliance tests.

3. Compact Antenna Test Range (CATR)

Used for mmWave beamforming simulation.

Environmental & Mechanical Design Considerations

Designing a 5G OTA test chamber also involves:

- Temperature control

- Humidity stability

- Low-vibration flooring

- Precision turntable alignment

- Calibration automation

Even slight mechanical shifts can introduce errors in mmWave testing.

Challenges in 5G OTA Testing

- Beamforming complexity

- Multi-antenna MIMO configurations

- Device miniaturization

- Higher frequency losses

- Repeatability across labs

With 5G Advanced and 6G on the horizon, OTA testing complexity will only increase.

Performance Optimization Techniques

To improve OTA chamber performance:

- Optimize absorber layout

- Regular calibration

- Maintain shielding integrity

- Use advanced probe arrays

- Implement automated test scripts

Proper maintenance ensures long-term measurement accuracy.

Real-World Applications

OTA test chambers are used in:

- Smartphone manufacturing

- Automotive V2X validation

- IoT certification labs

- Telecom R&D centers

- Defense RF testing

Every 5G-enabled device on the market has likely undergone OTA validation.

Pro Tip💡

For mmWave testing, even cable routing inside the chamber can impact results. Always use low-reflection materials and minimize metallic exposure near the DUT. Precision in setup equals precision in performance.

The Future of 5G OTA Chambers

As 5G evolves toward:

- Massive MIMO

- AI-driven beam management

- 6G Terahertz bands

OTA chambers will require:

- Higher absorber efficiency

- Smaller wavelength accuracy

- Advanced automation

- Digital twin simulation integration

Testing infrastructure must evolve alongside wireless innovation.

A 5G OTA test chamber is more than just a shielded room—it’s a precision-engineered RF ecosystem. From absorber materials to measurement algorithms, every element plays a role in ensuring device performance, compliance, and user satisfaction.

With growing reliance on mmWave and beamforming, OTA testing has become one of the most critical validation stages in modern wireless development.

As networks expand and devices multiply, mastering OTA chamber design and performance optimization will define the next generation of wireless excellence.

Frequently Asked Questions

1. What is the purpose of a 5G OTA test chamber?

It measures real-world antenna and RF performance without physical cable connections.

2. Why is OTA testing required for 5G?

Because 5G devices use integrated antennas and beamforming, conducted testing alone is insufficient.

3. What is the difference between Sub-6 GHz and mmWave OTA testing?

Sub-6 focuses on coverage and general radiation, while mmWave emphasizes beamforming and high-frequency precision.

4. What standards apply to 5G OTA testing?

Standards from CTIA, 3GPP, FCC, and ETSI guide certification and compliance.

5. How often should an OTA chamber be calibrated?

Calibration is typically performed periodically, depending on lab standards and regulatory requirements.