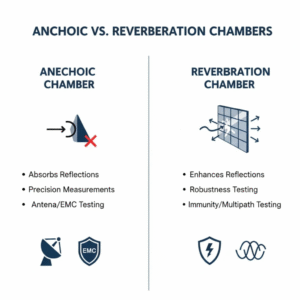

Anechoic vs. Reverberation Chambers: Choosing the Right Test Environment for Your Application

What is an Anechoic Chamber?

An anechoic chamber is a specially designed room that absorbs reflections of electromagnetic waves or sound waves. The word “anechoic” literally means “without echo.”

These chambers are lined with absorptive materials such as RF absorber foam for electromagnetic testing or wedge-shaped acoustic foam for sound testing. They are also shielded from external interference, making them ideal for simulating a free-space environment.

Key Features:

- Walls, ceilings, and floors lined with absorber materials

- Shielding to block external RF or acoustic noise

- Creates a quiet, interference-free test environment

- Often designed in pyramid or wedge structures to absorb reflections

Typical Applications:

- Electromagnetic Compatibility (EMC) testing

- Antenna performance testing

- Radar cross-section (RCS) measurements

- Acoustic testing for microphones, speakers, and vehicles

What is a Reverberation Chamber?

A reverberation chamber is designed to create a highly reflective environment where electromagnetic or acoustic waves bounce repeatedly off the walls. Instead of eliminating reflections, it maximizes them to create a statistically uniform field distribution.

These chambers usually have metal walls with little to no absorptive material. Some even use mechanical stirrers (metal paddles) to vary the distribution of reflections inside the room.

Key Features:

- Metallic reflective surfaces

- High field strength with minimal absorber use

- Mechanical stirrers for uniform distribution

- Simulates a multipath propagation environment

Typical Applications:

- Electromagnetic susceptibility and immunity testing

- Radiated power measurements for devices

- Stress testing in high field strength conditions

- Military and aerospace system evaluations

Anechoic vs. Reverberation Chambers: The Core Difference

At the simplest level:

- Anechoic chambers eliminate reflections to simulate free-space conditions.

- Reverberation chambers enhance reflections to test how devices perform in real-world multipath or high-stress environments.

Comparison Table: Anechoic vs. Reverberation Chambers

| Feature / Parameter | Anechoic Chamber | Reverberation Chamber |

|---|---|---|

| Primary Purpose | Absorbs reflections to simulate free space | Enhances reflections for stress testing |

| Wall Design | Foam absorbers (pyramid/wedge) | Metallic reflective walls |

| Field Environment | Quiet, interference-free | Uniform, multipath-rich environment |

| External Noise Shielding | High | High |

| Best For | Antenna/RF/acoustic performance testing | Immunity, stress, and power testing |

| Test Accuracy | High precision, controlled environment | Realistic, statistical environment |

| Cost | Higher due to absorber materials | Lower (less absorber required) |

| Applications | EMC compliance, RCS, audio testing | EMC immunity, aerospace, defense systems |

Advantages of Anechoic Chambers

- Accurate Results – By eliminating reflections, they provide highly precise measurements of antennas, devices, or acoustic systems.

- Free-Space Simulation – Ideal for testing devices that operate in open environments.

- Low Interference – Shielding ensures outside noise doesn’t affect test results.

- Versatility – Suitable for both electromagnetic and acoustic testing.

Advantages of Reverberation Chambers

- Efficient Stress Testing – Can expose devices to higher field strengths with lower input power.

- Uniform Field Distribution – Mechanical stirrers ensure devices experience multipath propagation, mimicking real-world conditions.

- Lower Cost of Construction – Requires fewer absorber materials compared to anechoic chambers.

- Scalability – Easily accommodates larger test objects like vehicles or aerospace systems.

Which Chamber Should You Choose?

The right chamber depends on your testing goals:

- Choose an anechoic chamber if:

- You need precise, reflection-free results.

- You’re testing antennas, sensors, or consumer electronics.

- Free-space conditions are essential for measurement accuracy.

- Choose a reverberation chamber if:

- You need to test device resilience under stress or multipath conditions.

- Your application involves military, aerospace, or defense equipment.

- You want to evaluate system performance in high electromagnetic environments.

Real-World Examples

- Anechoic Chamber Use Case

A smartphone manufacturer uses an anechoic chamber to test antenna efficiency and ensure that the device performs optimally in real-world usage. - Reverberation Chamber Use Case

A defense contractor tests communication systems in a reverberation chamber to ensure reliability in environments with high interference, such as on the battlefield.

Both anechoic and reverberation chambers are indispensable in the world of EMC, RF and acoustic testing. Anechoic chambers provide the precision of free-space simulation, while reverberation chambers deliver robustness by recreating challenging real-world environments.

When choosing between the two, consider your testing goals, budget, and application area. For antenna performance and accuracy-driven testing, anechoic chambers are ideal. For stress testing and immunity evaluation, reverberation chambers are the better option.

By understanding their strengths and limitations, you can confidently select the right test environment to ensure your products meet compliance standards and perform reliably in the real world.