How to Select Honeycomb Core for Your Application

Introduction

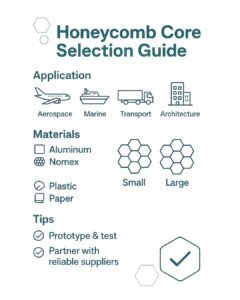

Honeycomb cores have become indispensable in engineering and design due to their unique combination of lightweight, high strength, and rigidity. They are used extensively in aerospace, marine, transportation, architecture, industrial manufacturing, and packaging industries. However, selecting the right honeycomb core for your application requires careful evaluation of material type, mechanical properties, cell size, thickness, environmental resistance, and cost-effectiveness.

This guide will help you understand the fundamentals of honeycomb core selection to ensure your panels and sandwich structures achieve optimal performance for their intended use.

Types of Honeycomb Core Materials

- Aluminium Honeycomb Core

Properties:

- High strength-to-weight ratio

- Excellent rigidity

- Good thermal conductivity

- Corrosion resistance (with proper surface treatment)

Applications:

Aerospace panels, floors, automotive impact structures, marine panels, cleanroom panels, railway interiors, and architectural facades.

Why choose aluminium honeycomb cores?

They provide superior structural support while keeping weight minimal, essential for fuel efficiency and structural stability in aerospace and transportation.

Nomex Honeycomb Core (Aramid Paper)

Properties:

- Lightweight and strong

- Fire-resistant and self-extinguishing

- Excellent dielectric and insulating properties

- Good fatigue resistance

Applications:

Aircraft interiors (floors, partitions, overhead bins), randoms, sandwich panels for racing cars, and electrical insulation applications.

Why choose Nomex cores?

They are ideal where fire safety, electrical insulation, and lightweight structures are critical, particularly in aerospace and defence industries.

Paper Honeycomb Core

Properties:

- Low cost and lightweight

- Environmentally friendly (recyclable)

- Adequate compressive strength for non-structural uses

Applications:

Furniture, doors, partitions, packaging pallets, protective packaging for shipping.

Why choose paper honeycomb cores?

When cost and environmental sustainability are primary factors, and mechanical strength requirements are minimal.

Thermoplastic Honeycomb Core (Polypropylene)

Properties:

- Lightweight with moderate strength

- Excellent moisture resistance

- Chemical resistance and recyclability

- Good energy absorption

Applications:

Marine components, automotive interiors, packaging, building panels, and temporary structures.

Why choose thermoplastic honeycomb cores?

They are ideal for wet environments or applications requiring easy recycling and impact energy absorption.

Steel and Titanium Honeycomb Core

Properties:

- Extremely high mechanical strength

- High temperature resistance

- Corrosion resistance (especially titanium)

Applications:

Heat shields, aerospace engine components, missile structures, and extreme structural environments.

Why choose steel or titanium cores?

When ultra-high strength and temperature resistance are needed despite the added weight and higher cost.

-

Cell Size Considerations

What is cell size?

Cell size refers to the diameter of the individual cells within the Honeycomb Structure. Common sizes range from 3 mm (small) to 12 mm (large).

Smaller Cell Size (3-6 mm)

- Advantages: Higher compressive and shear strength, better surface finish support, and improved impact resistance.

- Applications: Aerospace panels, high-strength flooring, structural panels where strength is critical.

Larger Cell Size (9-12 mm or above)

- Advantages: Lower density, reduced cost, and lighter weight.

- Applications: Non-structural panels, packaging cores, partitions, and decorative panels.

Selecting the Right Honeycomb Core for Your Application

Choosing the right cell size is a trade-off between strength and weight.

Core Thickness and Density

Thickness

Thinner cores (<10 mm)

Used where minimal thickness is required, such as aircraft cabin partitions or furniture panels.

Thicker cores (20-50 mm or higher)

Increase stiffness dramatically without adding much weight. Ideal for flooring, cargo panels, and load-bearing applications.

- Density

Higher density cores provide greater mechanical strength and compressive resistance, but increase weight and cost. Always check manufacturer datasheets for specific mechanical property values based on density.

Mechanical and Performance Requirements

Before selecting a core, analyse:

✅ Compressive Strength – Resistance to crushing forces perpendicular to the plane.

✅ Shear Strength – Resistance to sliding forces parallel to the plane.

✅ Fatigue Resistance – Ability to withstand repeated loading without degradation.

✅ Impact Resistance – Essential for panels exposed to dynamic forces or collisions.

Your application’s mechanical demands will dictate whether you need aluminium, Nomex, thermoplastic, or paper cores, and what density or thickness is optimal.

Environmental and Operational Factors

Consider where and how your panel will be used:

🌧️ Moisture Exposure: Avoid paper cores. Aluminium (with proper coating) and thermoplastic cores perform well.

🔥 Fire Resistance: Use Nomex or metallic cores for fire-critical environments. Thermoplastics are generally not fire-resistant.

⚡ Electrical Insulation: Nomex is ideal due to its dielectric properties.

🌡️ Temperature Extremes: Aluminium, titanium, or Nomex cores handle high temperatures better than thermoplastics.

Adhesive and Compatibility Considerations

Honeycomb cores are typically bonded to skins (face sheets) using adhesives. Ensure:

✔️ Compatibility between core material and adhesive for maximum bond strength.

✔️ Surface treatment of cores (especially aluminium) to promote adhesion and prevent corrosion.

✔️ Proper curing temperatures do not damage thermoplastic or paper cores.

Cost vs Performance Analysis

Finally, balance performance needs with project budget:

- High-budget, high-performance projects: Aluminium and Nomex honeycomb cores.

- Mid-budget, moisture-resistant applications: Thermoplastic honeycomb cores.

- Low-budget, non-structural applications: Paper honeycomb cores.

Discuss options with suppliers to source cost-effective solutions while meeting technical specifications.

Choosing the right Honeycomb Core is not just about picking a material; it requires evaluating mechanical properties, environmental compatibility, adhesive bonding, and cost efficiency. Whether you are designing aircraft panels, automotive interiors, marine decks, or simple packaging pallets, the right core selection ensures your product performs efficiently, lasts longer, and meets industry standards.

Partner with experienced manufacturers and test samples before finalising your design to ensure optimal results.

Top 5 FAQs

1. Which honeycomb core is best for aircraft applications?

Aluminium and Nomex honeycomb cores are widely used in aircraft for their high strength-to-weight ratio and fire resistance.

2. How does honeycomb core cell size affect weight?

Larger cell sizes reduce weight and cost but offer lower mechanical strength compared to smaller cells.

3. Can thermoplastic honeycomb cores replace aluminium cores?

Only in applications with lower strength requirements, moisture exposure, and where recyclability is desired.

4. What is the maximum temperature aluminium honeycomb cores can withstand?

Aluminium cores can withstand temperatures up to 177°C (350°F) and higher, depending on alloy and treatment.

5. Is paper honeycomb core waterproof?

Paper cores absorb moisture and lose mechanical integrity in humid or wet environments.