Modern architecture and industrial construction demand materials that are strong, durable, and lightweight. One such material revolutionising reinforced door manufacturing is the Honeycomb Core. But what makes honeycomb cores ideal for building reinforced doors? Let’s explore in depth.

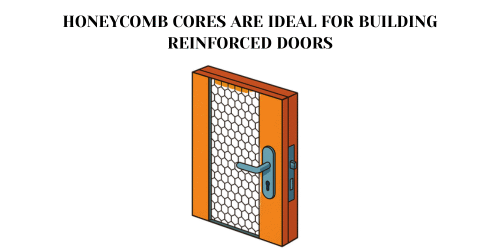

What Are Honeycomb Cores?

Honeycomb cores are structural panels made from thin sheets of materials like Aluminium Honeycomb or paper-based products, expanded to form a hexagonal Honeycomb Structure. This unique geometry mimics natural honeycomb structures, providing exceptional strength-to-weight ratios.

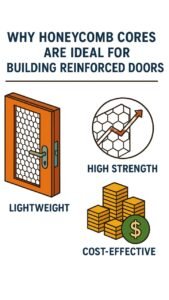

Lightweight Yet High Strength

One of the biggest advantages of using honeycomb cores in reinforced doors is their lightweight property without compromising strength. Traditional solid materials like steel or hardwood increase the door’s weight, requiring heavy-duty hinges and additional support frames. Honeycomb cores, on the other hand, reduce overall door weight by up to 50-70% while maintaining comparable structural strength. This improves installation ease and reduces structural load on buildings.

Excellent Compression and Shear Strength

Due to their geometry, honeycomb cores distribute stress efficiently, offering excellent compression and shear strength. This makes reinforced doors with honeycomb cores highly resistant to dents, impacts, and deformation. As a result, they are widely used in security doors, fire-rated doors, and industrial access doors where durability and reliability are critical.

Thermal and Acoustic Insulation Benefits

Beyond mechanical strength, honeycomb cores offer insulating properties. The air pockets within the core act as barriers to heat and sound transmission. This enhances the door’s thermal insulation performance, keeping interiors comfortable and energy-efficient. Similarly, it reduces sound transmission, making Honeycomb Core doors ideal for office partitions, hospital rooms, and high-privacy environments.

honeycomb core

Cost-Effective Manufacturing

Honeycomb core panels are cost-effective compared to solid panels. Their manufacturing process uses minimal raw material while achieving high strength, making them an economical choice for door manufacturers. Reduced material weight also translates to lower transportation and handling costs.

Eco-Friendly and Sustainable

Most honeycomb cores are made from recyclable materials such as aluminium or kraft paper, aligning with modern sustainability goals. Their lightweight nature further reduces the carbon footprint during transport and installation, making them an environmentally responsible choice.

Design Versatility

Honeycomb cores can be sandwiched between various skin materials, including steel sheets, Aluminium Honeycomb, fibreglass, or wood veneers, depending on the application. This design versatility allows manufacturers to create doors suitable for security, aesthetics, fire resistance, and moisture resistance, all customised as per project requirements.

Applications in Reinforced Doors

Some common applications include:

- Security Doors:Enhanced strength against forced entry.

- Fire Doors:Fire-resistant skin combined with honeycomb’s stability.

- Industrial Doors:High durability with minimal weight for frequent operations.

- Cleanroom and Lab Doors:Moisture-resistant skins with honeycomb cores for sterile environments.

Honeycomb cores offer the perfect combination of strength, lightweight, insulation, sustainability, and cost-efficiency, making them ideal for reinforced door manufacturing. Whether for security, industrial, or architectural applications, honeycomb core doors ensure long-lasting performance with minimal maintenance. As the demand for innovative building materials grows, honeycomb cores will continue to play a significant role in modern construction and door manufacturing.

Looking to build stronger, lighter doors with honeycomb cores? Contact us today to get the best solutions for your projects.