What Is an EMI Chamber and Why Is It Essential for EMC Testing?

Electronic devices are everywhere in today’s increasingly connected world, ranging from smartphones to medical equipment and aerospace systems. However, these devices often emit and receive electromagnetic signals that can cause interference, leading to malfunction or performance issues. This is where electromagnetic interference chambers (EMI chambers) come into play.

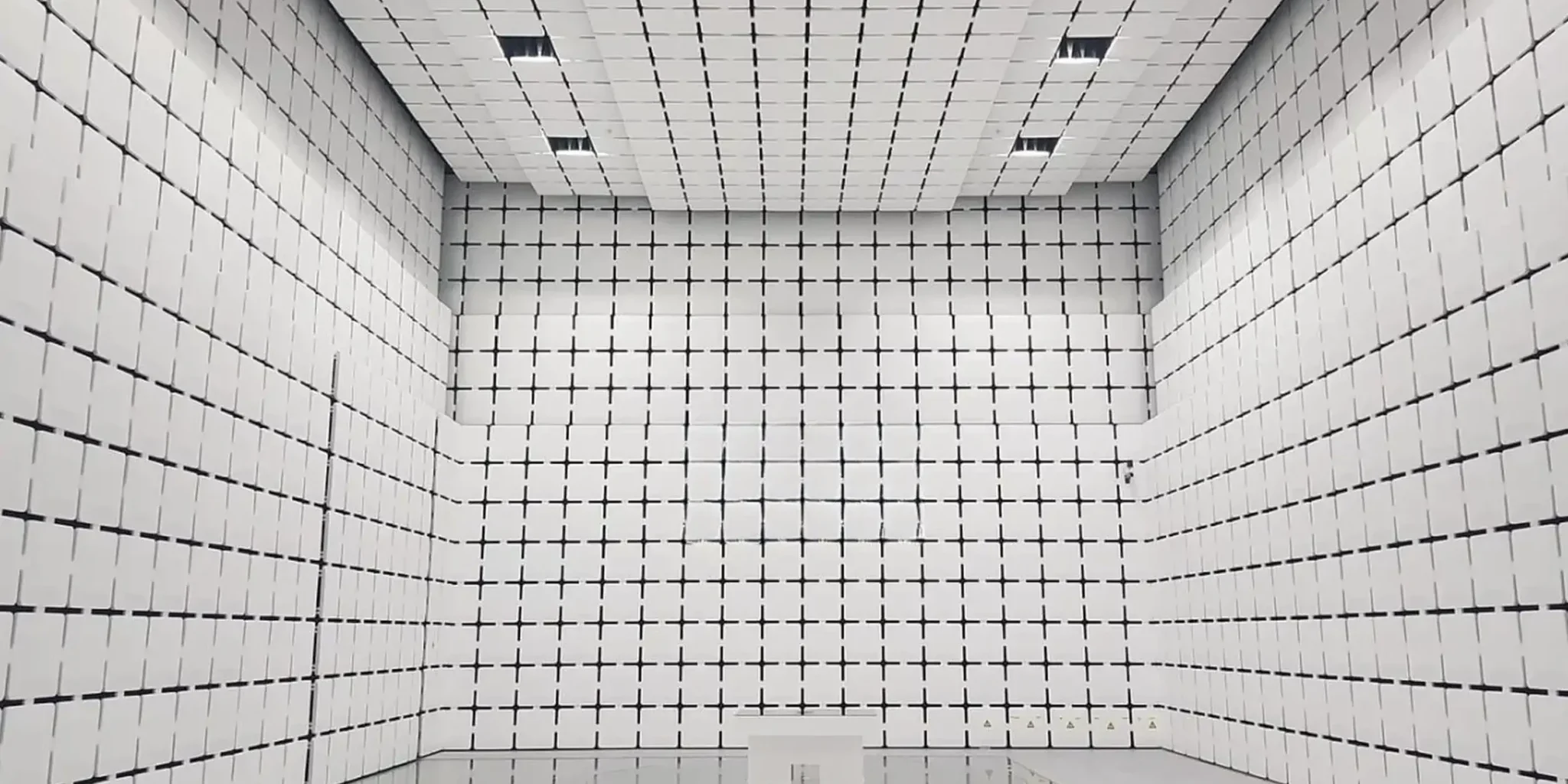

An EMI chamber is a specially constructed room used to test the electromagnetic compatibility (EMC) of electronic equipment. It creates a controlled, interference-free environment where engineers can evaluate how a device behaves under various electromagnetic conditions. These chambers are essential for ensuring that products meet international EMC standards and perform reliably in real-world scenarios.

By isolating a device from external RF (radio frequency) noise and suppressing internal emissions, EMI chambers enable precise testing that’s crucial for industries like defense, automotive, telecommunications, and healthcare.

Types of EMI Chambers: Anechoic, Semi-Anechoic, and Reverberation Explained

There are several types of EMI chambers, each designed for specific testing needs and performance levels. Here’s a breakdown of the three most commonly used chamber types:

Anechoic Chambers

Anechoic chambers have RF-absorbing materials on all six sides (walls, ceiling, and floor). These materials eliminate electromagnetic wave reflections, resulting in a “free-space” environment suitable for radiated emission and immunity testing. They are commonly used for antenna testing and complete compliance EMC testing.

Semi-Anechoic Chambers

Semi-anechoic chambers are similar to anechoic chambers but have a conductive, metallic floor instead of absorptive materials. This setup allows for the testing of equipment in real-world ground-reflective scenarios. These chambers are commonly used for pre-compliance testing and are suitable for testing large devices or systems.

Reverberation Chambers

Reverberation chambers use reflective surfaces and mechanical stirrers to create a statistically isotropic and homogeneous electromagnetic environment. This makes them ideal for immunity testing at high field strengths. They’re known for efficient high-power testing and are often used in military and aerospace applications.

How EMI Chambers Are Designed to Suppress Electromagnetic Interference

The effectiveness of an EMI chamber depends on its design and construction. Key components include:

- RF Shielded Enclosure: The walls are made of conductive materials like steel or copper, which block external electromagnetic signals.

- Absorber Materials: RF absorbers (such as pyramidal foam) line the interior to reduce internal wave reflections and resonant frequencies.

- Filtered Power and Signal Lines: All power and data lines entering the chamber are filtered to prevent EMI leakage.

- Honeycomb Vents and Waveguides: These allow for airflow or light without compromising RF isolation.

- Seamless Doors and Gaskets: Specially designed doors with conductive gaskets maintain shielding integrity when closed.

Together, these elements ensure that the chamber effectively isolates the test environment from unwanted EMI, allowing for accurate EMC assessments. Without such precision, manufacturers risk releasing products that might fail in real-world electromagnetic conditions—jeopardizing both user safety and brand reputation.

EMI chambers are indispensable tools for achieving reliable and compliant electronic designs. Whether you’re building a smartphone, a satellite, or a pacemaker, EMI testing in a properly designed chamber ensures your product can coexist with other electronics without interference or failure.

Need EMI Chamber services? Contact us today for a consultation!