GENERAL

The filter herein described shall be designed for filtering of radio frequency interference and to meet the requirements of Military Specifications MIL-F-15733, where applicable. These filters may be used with other electrical devices to enable the devices to meet the requirements of MIL-I-26600, MIL-I-16910, MIL-I-6181, MIL-I-11748, MIL-STO-461, 462, 463, FED-STD-222,

And FCC Specification. Also, DCA specifications and others developed for special equipment and systems applications.

ELECTRICAL

CURRENT RATING: The filters shall be capable of carrying full-rated current with a heat rise not exceeding 25°C above ambient temperature. The filters shall be capable of withstanding 150% of rated current overload for 15 minutes without any deterioration.

VOLTAGE: The filters shall be capable of operating continuously at full-rated voltage and of withstanding an over-voltage test of twice the rated voltage for one minute. Maximum voltage drop shall not exceed 2 volts when measured in accordance with MIL-F-15733. Maximum operating temperature: 85°C.

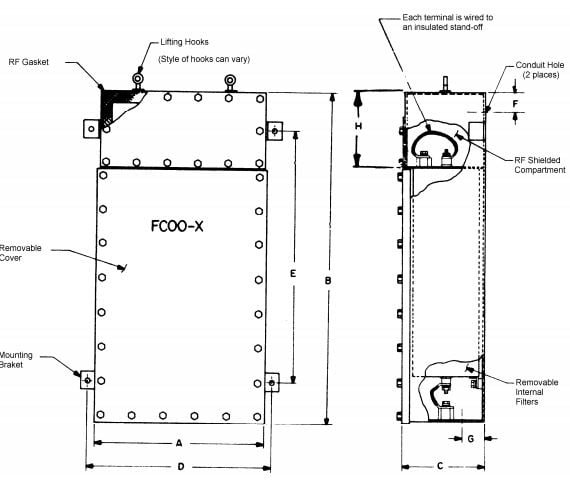

MECHANICAL

CASE: The inner cases of each filter shall be made of C.R.S. 16 GA. min. Each phase filter shall be individually replaceable. All internal filters are hermetically sealed.

TERMINALS: The Military EMI Filters shall be made of high temperature alumina ceramic and shall be leak proofed. The ceramic terminal shall have a flexible insulated lead, one end of which is permanently attached to the terminal, the other end in a permanently affixed lug mounted on .7 approved flame-retardant stand-off insulator secured with a suitable screw. All connections shall be made only at the stand-offs.

IMPREGNANT: Where applicable the Impregnant shall be non-flammable as classified by U.L. and MIL-F-15733.

CONSTRUCTION: Input and output terminals shall be completely enclosed in Military EMI Filters. Covers on the input and output RF shielded compartments shall be held down with screws, Gasketing shall be used between the cover and the inside fitting flange to maintain Military EMI Filters. Internal components shall be mounted and fixed to prevent damage when subjected to applicable shock and vibration tests.

FINISH: All filter cases shall be made rust proof by painting over primer. All unfinished grounding surfaces are protected by suitable plating.