How to Install and Maintain Foam-Based RF Absorbers

Foam-based RF absorbers are essential components in anechoic chambers and RF testing environments. These absorbers minimize unwanted reflections, simulate free-space conditions, and improve the accuracy of measurements in electromagnetic compatibility (EMC), antenna, and radar testing. But simply installing absorbers isn’t enough—their proper installation and maintenance are key to long-term chamber performance.

At Diamond Microwave Chambers Ltd, we specialize in designing and retrofitting high-performance RF chambers using premium-quality absorbers. This blog provides a practical guide on how to install, maintain, and know when to upgrade your foam-based RF absorbers.

Chamber Retrofitting: When and Why to Upgrade Your RF Absorbers

Over time, even the best absorbers degrade due to environmental factors such as dust, humidity, temperature fluctuations, and wear-and-tear. This leads to reduced performance and inaccurate results. Retrofitting your chamber ensures it remains effective and compliant with modern standards.

When to Consider Retrofitting:

- Visual Degradation: If the absorbers appear faded, brittle, or discolored, their material properties may be compromised.

- Loss in Performance: Reduced reflectivity levels or inconsistent test results indicate absorber deterioration.

- Outdated Technology: Older absorber models may not support today’s wideband frequency requirements or EMC standards.

- Damage from Use or Transport: Mechanical or thermal damage from repeated chamber usage, equipment collisions, or exposure to extreme conditions can warrant replacement.

- Regulatory Compliance: New industry regulations or customer demands may require chamber upgrades.

Why Choose Diamond Microwave Chambers Ltd?

- We offer custom retrofitting services for all types of RF chambers, tailored to your current and future testing needs.

- Our expert team ensures minimal downtime, working around your production or testing schedules.

- We use advanced foam-based absorbers that deliver high reflectivity loss and excellent broadband performance.

How RF Absorbers Reduce Reflections in Anechoic Chambers

Anechoic chambers are designed to create a “quiet zone” free from echoes or electromagnetic interference. Foam-based RF absorbers make this possible by absorbing incoming electromagnetic energy rather than reflecting it.

How It Works:

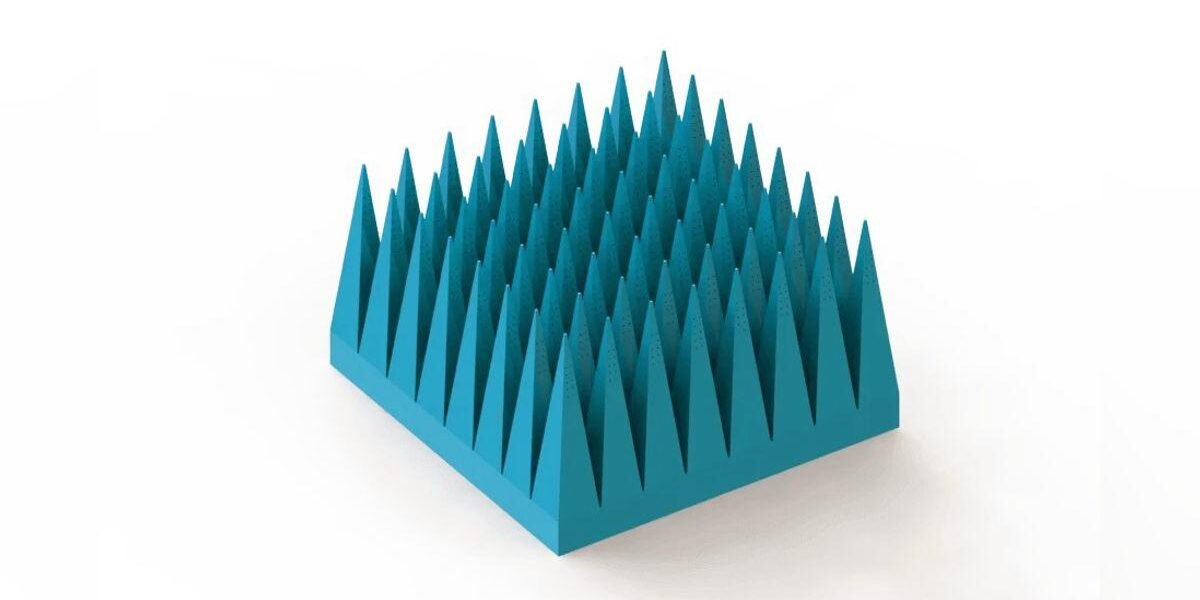

- Material Composition: These absorbers are typically made of carbon-loaded polyurethane foam that converts RF energy into heat.

- Geometric Design: The pyramidal or wedge shape of the foam helps trap and gradually attenuate electromagnetic waves.

- Broadband Absorption: High-quality foam absorbers can cover a wide range of frequencies, from hundreds of MHz to tens of GHz.

Key Benefits:

- Reduces Reflections: Significantly lowers background noise and interference within the chamber.

- Improves Accuracy: Ensures that measurements reflect actual equipment performance without false signals or echoes.

- Supports Advanced Testing: Essential for 5G, radar, satellite, automotive EMC, and wireless device evaluations.

When properly installed, Foam-Based RF Absorbers can deliver reflectivity performance of -60 dB or better, enabling highly accurate testing environments.

Best Practices for Installation and Maintenance

Correct installation and routine maintenance extend the lifespan of your RF absorbers and maintain chamber performance.

Installation Tips:

- Site Preparation: Make sure the walls and surfaces of the chamber are clean, dry, and structurally stable.

- Orientation and Placement: Follow layout plans carefully. Misaligned absorbers can cause performance dips.

- Adhesive Selection: Use RF-compatible adhesives that won’t interfere with absorber function or emit contaminants.

- Avoid Gaps: Ensure absorbers are installed tightly together without gaps to prevent signal leakage or reflections.

Professional installation from a qualified team, like ours at Diamond Microwave Chambers Ltd, is highly recommended to ensure precision.

Maintenance Tips:

- Routine Inspections: Check every 6 to 12 months for visible signs of wear, mold, or dust accumulation.

- Dusting and Cleaning: Use vacuum systems or gentle air blowers to remove dust. Avoid water or harsh chemicals.

- Environmental Control: Keep temperature and humidity within recommended levels to preserve foam quality.

- Replacement Schedule: Depending on usage intensity and chamber conditions, plan for absorber replacement every 5–10 years.

Foam-based RF absorbers are the backbone of any high-performance anechoic chamber. Whether you are building a new chamber or managing an existing one, installation and maintenance are crucial for optimal results. And when performance begins to decline, retrofitting your absorbers is a cost-effective way to restore chamber functionality without a complete rebuild.

At Diamond Microwave Chambers Ltd, we provide industry-leading RF absorber solutions and expert retrofitting services to meet today’s evolving testing requirements. From design to installation and ongoing support, we’re here to help you maintain a world-class RF environment.

Ready to upgrade or maintain your RF chamber?

Contact Diamond Microwave Chambers Ltd today for expert installation and retrofitting services.