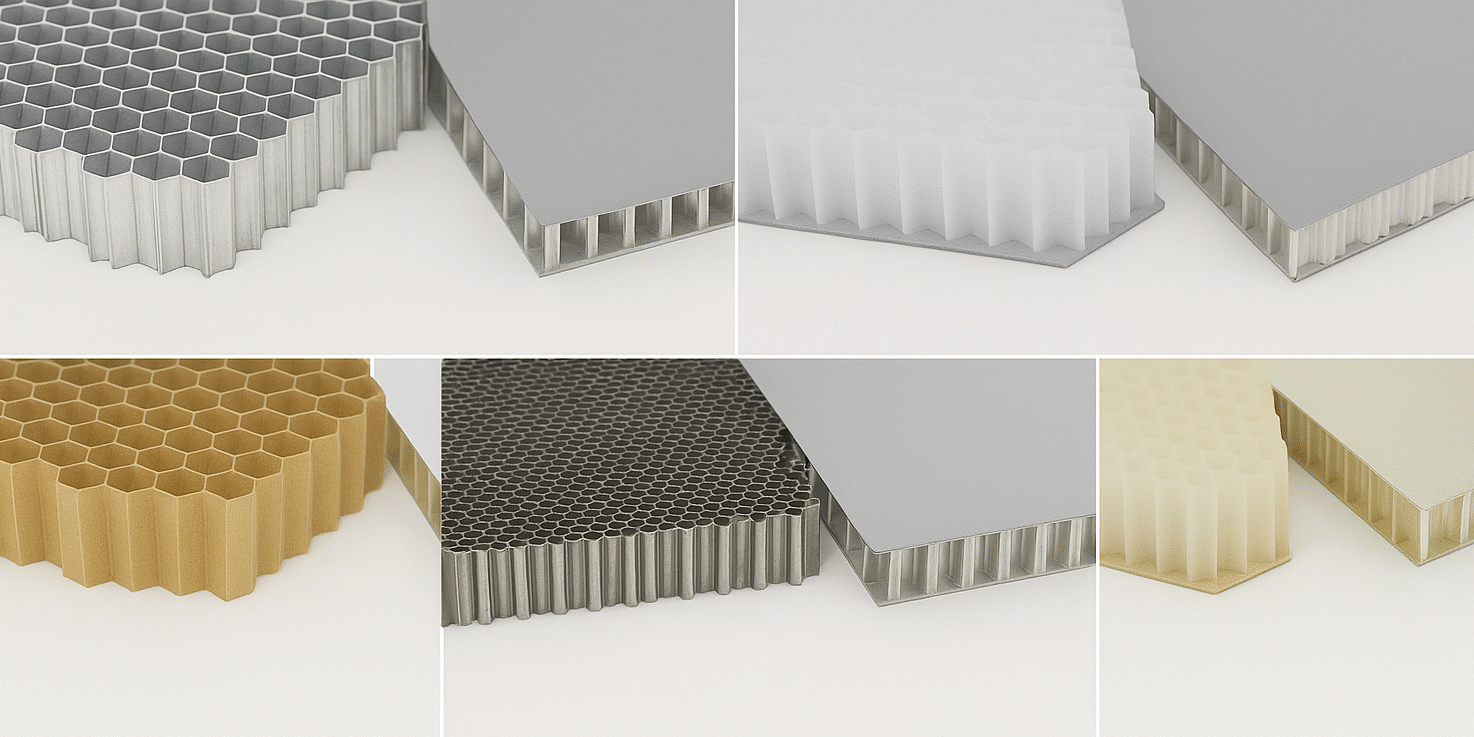

Honeycomb cores are hexagonal cell-structured lightweight materials. They are stiff and strong but extremely light. These materials find application in various industries, such as aircraft panels, automobile parts, packaging, and furniture.

Here, we shall discuss the different types of honeycomb cores and how you may select the one you need.

What Is a Honeycomb Core?

A honeycomb core is constructed in a hexagonal pattern that offers high strength while using minimal material. To create a panel, manufacturers place the core between two face sheets. This combination results in a lightweight yet highly durable structure, making it suitable for a wide range of applications.

Honeycomb Core Types

There are various types of DMC honeycomb cores depending on the material. All have their pros and cons and are applicable for specific purposes.

-

Aluminum Honeycomb Core

- High strength-to-weight ratio

- Corrosion resistant

- Can be utilized with high-temperature applications

- Generally applied in aerospace, automotive, and marine industries

Applicable for: Load-bearing parts and structural parts requiring low weight and strength.

-

Nomex (Aramid) Honeycomb Core

- Composed of aramid fiber and resin

- Chemical-resistant and fire-resistant

- Resistant to high temperatures

- Applied in aircraft interiors, trains, and fire-resistant spaces

Ideal for areas where fire safety is important.

-

Paper Honeycomb Core

- Composed of kraft paper glued together

- Inexpensive and environmentally friendly

- Easily recyclable

- Applied in standard packaging and furniture

Recommended for short- or low-load applications such as boxes or furniture panels.

-

Thermoplastic Honeycomb Core

- Made of plastic materials such as polypropylene

- Chemical- and water-resistant

- Very lightweight and can easily be molded

- Applied to car components and building panels

Best for humid environments and areas needing material flexibility

-

Fiberglass Honeycomb Core

- Corrosion-resistant and robust

- Very suitable for use in electrical insulation

- Applied to marine, electric, and industrial products

Best used for areas with moisture or chemicals.

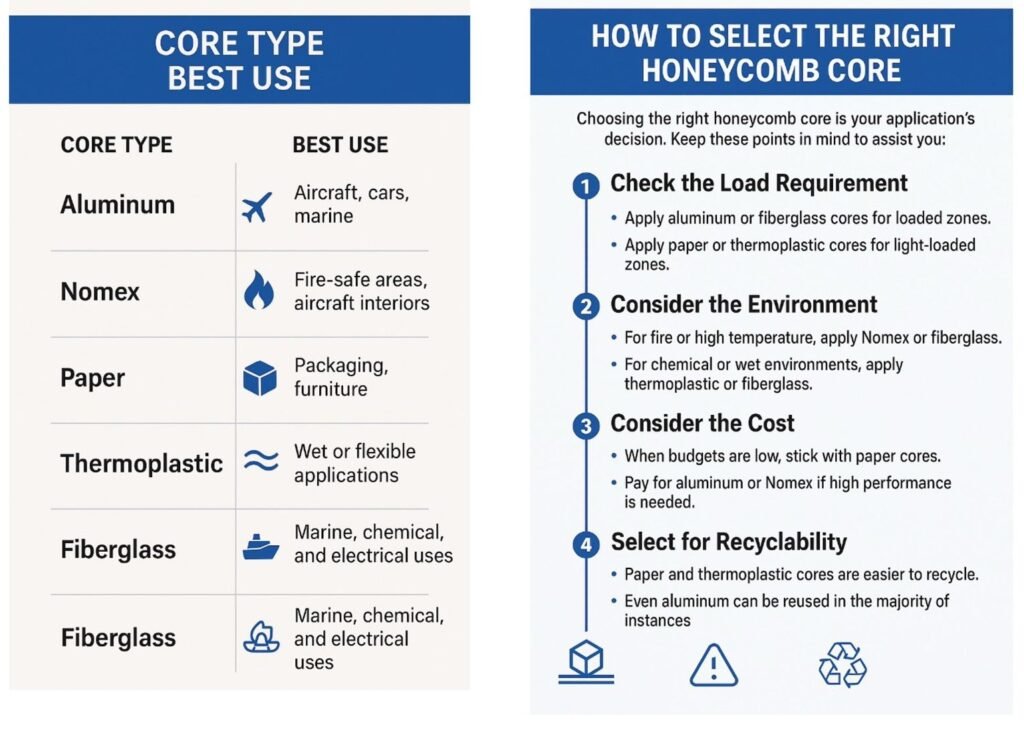

How to select the Right Honeycomb core

Choosing the right honeycomb core is your application’s decision. Keep these points in mind to assist you:

- Check the Load Requirement

- Apply aluminum or fiberglass cores for loaded zones.

- Apply paper or thermoplastic cores for light-loaded zones.

- Consider the Environment

- For fire or high temperature, apply Nomex or fiberglass.

- For chemical or wet environments, apply thermoplastic or fiberglass.

- Consider the Cost

- When budgets are low, stick with paper cores.

- Pay for aluminum or Nomex if high performance is needed.

- Select for Recyclability

- Paper and thermoplastic cores are easier to recycle.

- Even aluminum can be reused in the majority of instances.

Summary

Choose your DMC honeycomb core based on load, environment, cost, and recyclability. The right core makes your product easier to use and more durable.

Contact DMC today. Let’s see how we can help you achieve the dependable data you require.