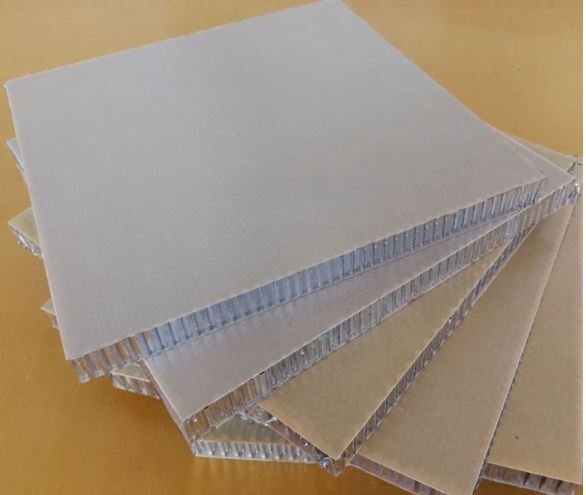

Fiberglass Honeycomb Panels

Fiberglass Aluminum Honeycomb Panel is made of fiberglass skins on both sides and core in aluminum honeycomb materials. These panels are highly durable and widely applied. Our company can make fiberglass honeycomb panels according to your needs and detail drawings.

Tips: Fiberglass skin and aluminum honeycomb core are two different materials, so it will be a galvanic difference between them. In the case of marine field applications, we do not recommend the use of this kind of honeycomb panel.

Features of fiberglass aluminum honeycomb panels:

- Weight: One of the primary reasons for utilizing aluminum honeycomb panels is that they exhibit excellent strength-to-weight ratios compared to traditional construction materials.

- Strength: The ability to configure panels with different materials allows us to create much stronger panels than one can achieve with solid structures. The skill, however, is in analyzing all of the material choices for meeting your specifications and then selecting those that will provide the most functionality at the lowest cost.

Structure: Fiberglass skins + Aluminum honeycomb core + Fiberglass skins.

1. Face skin: Fiberglass;

2. Bottom skin: Fiberglass;

3. Skin thickness: 0.3mm/ 0.6mm/ customized;

4. Core: Aluminum honeycomb;

5. Color of fiberglass skins: customized.

Advantages: Fiberglass honeycomb panel has higher compressive strength and lower core density when compared with balsa.

Packing details: Standard pallets/ plywood cases/ cartons.

Customizable: The production of our fiberglass honeycomb core panel are based on the requirements of our clients, who determine dimensions and other panel specifications.